College of Engineering Unit:

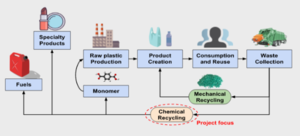

We are investigating the feasibility of a pilot plant to enable chemical recycling of plastics in Bali, Indonesia, to move towards a circular economy of plastic. Bali has some of the worst plastic waste pollution across the globe. Kuta and Legian, two of their most popular beaches, receive up to 60 tons of plastic waste per year1. Global Petrochemicals is interested in better management of waste through sorting, collection and recycling, and has begun a community collection and recycling pilot project in Bali. Additionally, Global Petrochemicals is interested in sourcing feed for a chemical recycling project from this facility. Chemical recycling involves using a chemical reactor to break the long polymer chains present in plastic, into smaller hydrocarbons which can then be used to manufacture new molecules and products (in a process known as pyrolysis).

Our team was tasked with two objectives;1. development of the refinement process for the pyrolysis oil (PyOil) leaving the pyrolysis reactor, and 2. improvement of the current waste collection and sorting facility to maximize economic value and household participation. For the refinery, the PyOil must be separated into 4 products: py-gas, light, medium, and heavy. The light and medium cuts will be fed to a steam cracker, while the py-gas will be fed directly to an ethylene plant. For the light and medium product, very low outgoing water and other contaminant concentrations are critical, so as to not foul the catalyst in the ethylene cracker. The plant must be designed to minimize the environmental and public health impact of all exit streams.

There are three main objectives for improving the waste sorting facility: quality, throughput and affordability. Collection of polyethylene is particularly desired as it will increase the quantity of py-gas feed to the ethylene plant, and is currently not focused on by independent waste collectors due to its lower value relative to other plastics. Another major focus will be increasing household participation in the plastics recycling program. The current waste collection service in Bali is voluntary with participation below the desired rate to support the PyOil production demands.

Throughout our project, there will be special attention paid to community and environmental safety. Waste must be properly disposed of, preventing environmental contamination, and potential risks to the community and workers must be eliminated or lowered to acceptable levels.

| Attachment | Size |

|---|---|

| 1023.61 KB |