College of Engineering Unit:

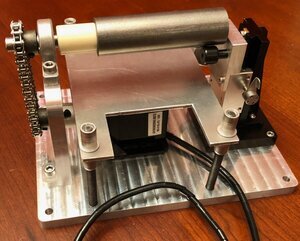

This project focused on creating a fixture that attaches to the base plate of the M450 metal 3D printer and rotates bar stock below the wire nozzle. The fixture will be used to rotate the rods at a constant speed so that the printer can evenly deposit the cladding onto the rods’ surface. Currently, the printer alone is unable to effectively clad curved surfaces. For this reason, the project team was tasked with designing and fabricating a fixture that allows for further research on the effects of cladding in metal additive manufacturing. The sponsors for this project are Dr. Burkan Isgor, Dr. Julie Tucker, and GRA Scott Bozeman of Oregon State University's material science department. By creating this fixture, the sponsors will be able to expand their testing capabilities and gather more insight pertaining to bonding metallurgy, microstructures, and corrosion protection of cladding.

The design process began with specifying the customer requirements from the sponsors and creating a variety of concepts to expand upon. After considering these requirements and consistently implementing design changes, the team finalized a design using Solid Works and moved on to manufacturing the fixture. The fixture is comprised of off the shelf components, team-fabricated components, and outsourced components using Xometry.

| Attachment | Size |

|---|---|

| 850.95 KB |