College of Engineering Unit:

The Sumobot competition is a friendly competition between three teams in the MIME 498 capstone course. Each match will feature a one-on-one showdown between two teams. There are three rounds in a match lasting one minute. The first team to win two rounds is victorious and moves on to the next match. The Sumobot competition is essentially a traditional sumo competition but with robots instead of humans.

Some important rules for the Sumobot competition to keep in mind are that there are no weapons of any sort allowed. Sumobots must weigh 3 kg or less to compete. A Sumobot can not exceed 20 cm in either width or length before the match, but after the start of the match, the Sumobot may extend out or exceed these constraints.

This year’s competition will feature fully autonomous robots, this means any type of remote control is not allowed. Instead, the Sumobots will rely on a program that tells the robot how to operate based on readings from sensors.

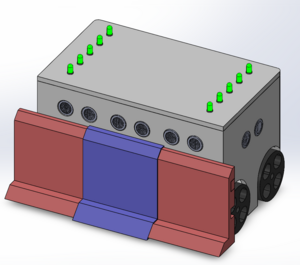

Team 609.1 kickstarted the project by brainstorming customer requirements and engineering specifications. The team came up with various designs and narrowed them down to a Sumobot with a rectangular body that features a deployable ramp subsystem. The team's Sumobot chassis and body are constructed out of aluminum sheet metal so that it is durable and strong. To sense opponents the robot utilizes 5 ultrasonic sensors and to sense the edge of the arena there are 2 IR (Infrared) sensors used. The robot is driven by four 12 V DC motors and powered by a 14.8 V Li-Po battery. All of these components are utilized and controlled by a program uploaded to an Arduino Mega board.

The team’s Sumobot features a unique deployable ramp subsystem. The reasoning behind the design decision was that the team wanted to increase the chance of coming into contact with the opposition. The deployable ramp system increases the width of the ramps from 20 cm to 35 cm. The ramps and gears are 3D printed and driven by a stepper motor mounted to the front of the Sumobot.

| Attachment | Size |

|---|---|

| 1.49 MB |